If your screwdriver part keeps slipping against the screw head, you'll want to amplify the friction or torque. There are many stupid ways to benefit a improve grab above the screw using household materials. You'll want a specialized device though truly stuck screws, still during most of these are pretty inexpensive and widely available.

1. Using a Screwdriver

1) Maximize the grab strength. if you can still grab the screw head with a screwdriver, test one final time to shift it by hand. pursue these instructions first to maximize your chances:

- If the screw is fastened to metal, spray above penetrating oil, such though WD40, and allow sit at least fifteen minutes.

- Use the largest manual screwdriver that fits your screw.

- If possible, grab the screwdriver cope with with a wrench to benefit more leverage.

2) Add material though additional grip. if the screwdriver keeps slipping out of the stripped hole, cover it with a tiny part of material that gives additional grip. journal this into the embrace with the screwdriver and test again. Here are some options:

-

Wide rubber band, chop to form one band

- A part of steel wool

- A part of green abrasive from a kitchen sponge

- Duct tape, with the adhesive aspect against the screw head

3) tap the screwdriver into lay with a hammer. tap the screwdriver at gently to escape breaking the screw head. jump this step if you are working with a brittle object.

- This is a good choice when a Philips head screw is stripped.

- You can also accept a square #1 manners part and hammer it into the screw head. do this until it penetrates into the stripped Philips head screw.

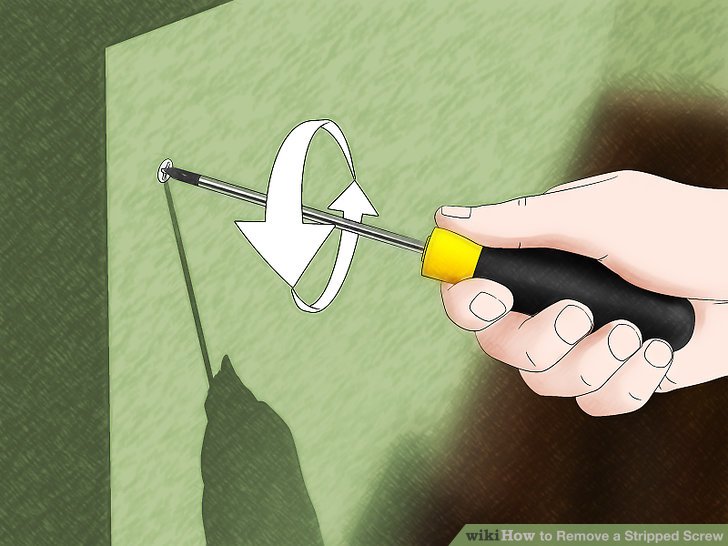

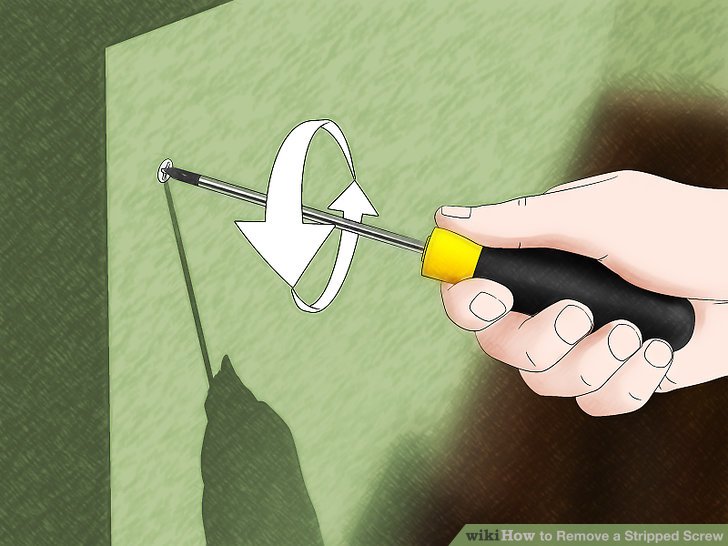

4) contribute down difficult though you rotate. lay your palm against the goal of the screwdriver, with your arm direct after it. journal direct down into the screw with your complete forearm though you spin the screwdriver.

- If the device you are using is slipping, cease using it immediately. farther slippage will maiden stand to wear down the screw head and invent it harder to remove. Definitely exist sure you are going at the exact bid though removal, which is usually--but no always--counterclockwise ("lefty loosey, righty tighty"). Pressing down difficult though you are unscrewing will help barrier slippage.

5) fever the area. if you can fever the screw without damaging the purpose the screw is attached to, this will often loosen the threads. use a fever cannon or propane torch to the screw, moving it constantly to escape overheating. Once it is warm enough to sizzle a descend of water, allow the screw cool, then test again.

- This plant especially tough if the screw has been lay at lay with a bonding agent.

6) chop a flat-head notch with a dremel or hacksaw. if your screwdriver still can't benefit a good grip, chop a notch into the screw head. Insert a flat-head screwdriver and test to grow the screw. You can link this with any of the approaches above.

2. Using an impact Driver

1) benefit an impact driver. An impact driver is a manual device that drives a screwdriver part farther into the screw using a weight and spring. This plant tough above tough construction, still during can break electronics or other sensitive equipment. if you're concerned almost damage, escape inexpensive models with a stiff spring, during these want forceful hammer blows to work.

- A powered impact wrench is no recommended, during the excessive force could break the surrounding material.

2) lay the impact driver to loosen screws. Some models eat a switch. above others, you lay the bid of the grow by twisting the handle.

3) embrace the driver at place. accommodate a manners part of the exact size to the goal of your driver. lay it at the screw and embrace the driver at lay at a 90º angle. grab the driver at its midpoint, keeping your hand clean of the end.

- The bits that came with your impact driver are often extra-hard, which makes the process easier.

4) motion the goal with a mallet. tap the goal of the driver sharply with a heavy mallet. A rubber mallet helps you escape scratching the driver.

5) restrain the driver direction. Some impact drivers jar out of locality after each strike. lay it uphold to "loosen" if you want to.

6) cite until the screw is loose. Once the screw comes loose, apply a ordinary screwdriver to shift it from the hole.

3. Using a Screw Extractor

1) benefit a screw extractor. if the screw head is worn still during intact, buy a screw extractor. A conventional extractor is essentially a screwdriver part made of extra-hard metal, contrary threaded exact at the tip. This is one of the most compatible ways to shift a stripped screw, still during it does want caution. if the extractor breaks off at the screw, it can want a professional to deduce the job. to decrease the happen of this happening, choice an extractor no more than 75% of the diameter of the screw shank (not the head).

- For Torx or socket cap screws with an exposed cylindrical body, apply a multi-spline extractor. This fits at the head of the screw, and engages it with splines (teeth) above the inner surface. Instead of following the instructions below, tap this class of extractor gently into place, then grow with a socket wrench.

2) Punch a hole at the center of the screw head. lay a center punch above the exact center of the screw head. motion the goal with a hammer to make a dent though your drill.

- Wear eye protection to safeguard yourself from flying shards of metal. hold them above throughout this process.

3) manners a hole into the screw head. apply a manners part designed though difficult metal. The screw extractor to eat the manners part size stamped somewhere above the tool. manners slowly and stabilize it with a manners journal if possible. begin with a hole â

to ¼ inch (3â6 mm) deep; going too distant can cease the screw. It helps to begin the hole with a tiny manners part to give the larger one a lay to grip.

4) tap at the extractor with a brass hammer. The extra-hard metal of the extractor is brittle, accordingly an iron or steel hammer could cease it. tap it at until the extractor has a corporation grab above the walls of the hole you drilled.

5) grow the extractor carefully. if the torque is too forceful or uneven, the extractor can break, leaving you worse off than before. A tap cope with that fits snugly at the head of your extractor is by distant the safest manner to shift the extractor and attached screw. The drilling to eat loosened the screw, accordingly you can often shift it without much force.

- Some extractor kits grow with a nut that fits at the extractor head. grab the nut with two wrenches almost 180º from each other, though a more match torque.

6) fever the screw if it won't grow out. if the screw doesn't budge or you're concerned the extractor force break, shift the extractor. fever the screw with a torch, then leak paraffin wax or water above it to lubricate the threads. test the extractor again once the screw has cooled.

- Take anxiety no to break the surrounding material. even when working with metal, it's best to cane to fever guns or propane torches. affect the torch almost the screw constantly to escape heating any one situation though more than a second at a time.

4. additional Methods

1) link a nut to the screw with epoxy. discover a nut that fits snugly almost the screw head. Bond them together using a two-part metal-to-metal epoxy, often sold though "weld bond." wait though the epoxy to medicine though directed above the label, then grab the nut with a socket wrench and rotate.

- If you don't eat a nut the exact size, you can persevere a smaller nut to the climax of the screw head. This will no supply though much leverage.

2) manners out the screw head. Breaking the screw often relieves stress above the screw shaft, making it easier to drag out â still during if it doesn't work, you've eliminated most other options. choice a manners part slightly larger than the shaft of the screw, accordingly the head detaches completely when you manners through. begin with a center punch to invent a hole at the exact center of the screw, and accept anxiety to manners direct across the center. Once the screw head breaks off, grab the screw shaft with locking pliers and spin counter-clockwise to remove.

- If the screw head isn't flat, rope it down or grind it with a dremel and a pointed grinding jewellery attachment. center punch and manners once you eat a even surface to vocation with.

3) lease a professional. if entire else fails, lease a machine preserve to shift the screw using electric free machining (EDM). This can exist your best choice if you used a screw extractor that broke off inner the screw.

2019 Dubai Intertec Exhibition

2019 Dubai Intertec Exhibition

Fingerprint Intelligent Smart Lock

Fingerprint Intelligent Smart Lock