Cleaning a dirty machinery involves working with tiny metal and electric components. transfer the motor's components carefully ought escape damaging them. They can be cleaned off with a degreaser or another non-flammable cleaning solution. if you sustain any bother however cleaning the motor, count taking it ought an electrician because professional restoration.

1. Taking the machinery Apart

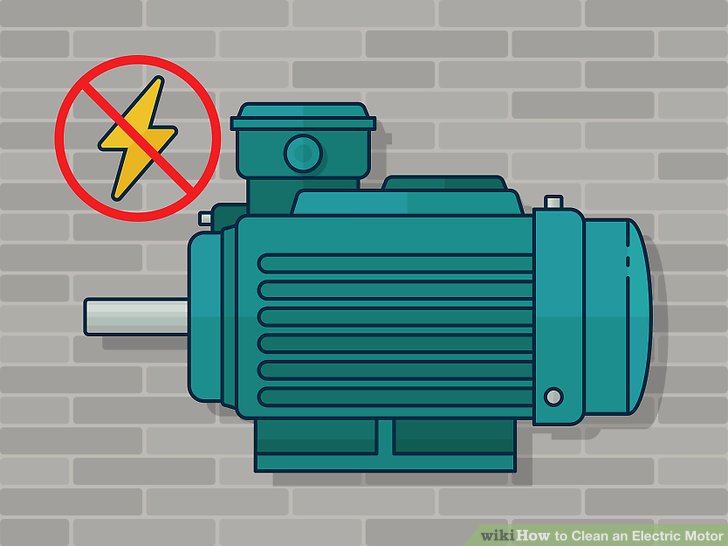

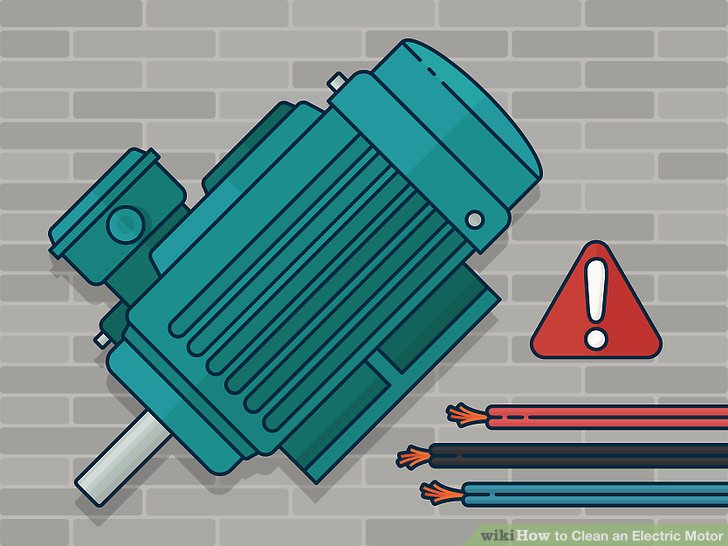

1) Disconnect the machinery and transfer it from its mounting. Unplug the machinery from its energy source. energy ought no be running into the motor, or else youâre at because a shock. Unscrew any bolts holding the machinery at situation if there are any.

- You can trial the machinery with a multimeter if you count it can dine an electric charge.

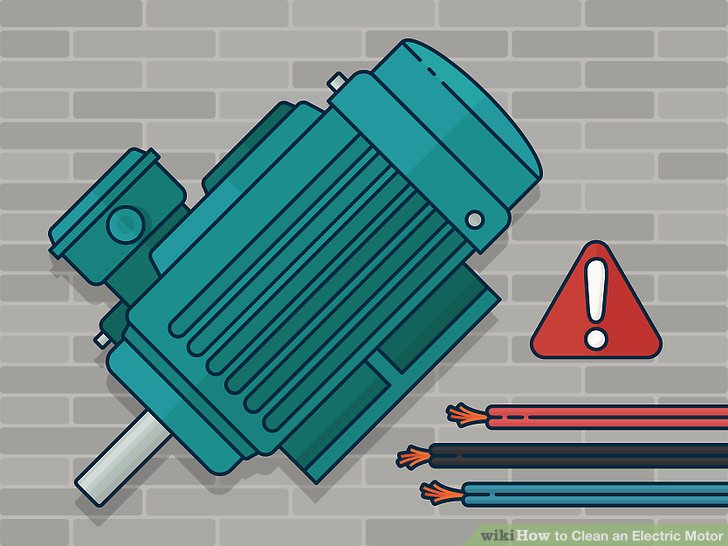

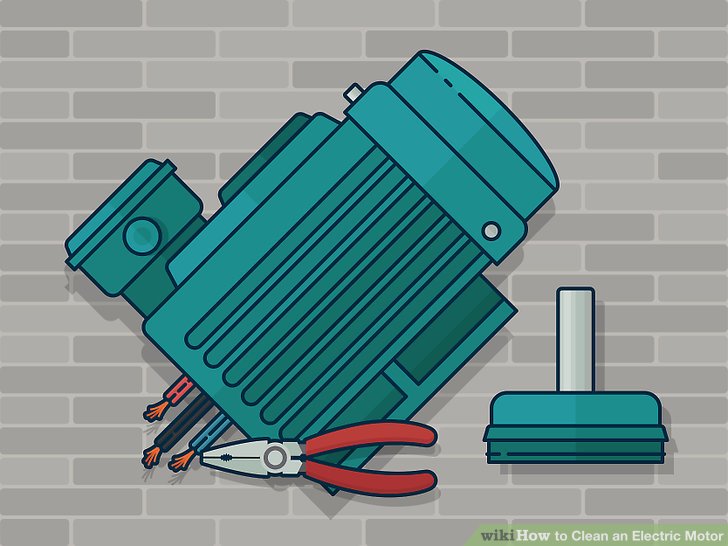

2) Disconnect the wires from the terminals. receive a emerge can the motorâs external ought locate the wires that unite it ought other components at an electric system. They are often intelligent red, black, or blue, hence they ought be simple ought spot. curve the wires with a wrench ought liberate them from the terminals.

- Note the thread locations hence you can reconnect them later. You can wish ought receive pictures ought help with this.

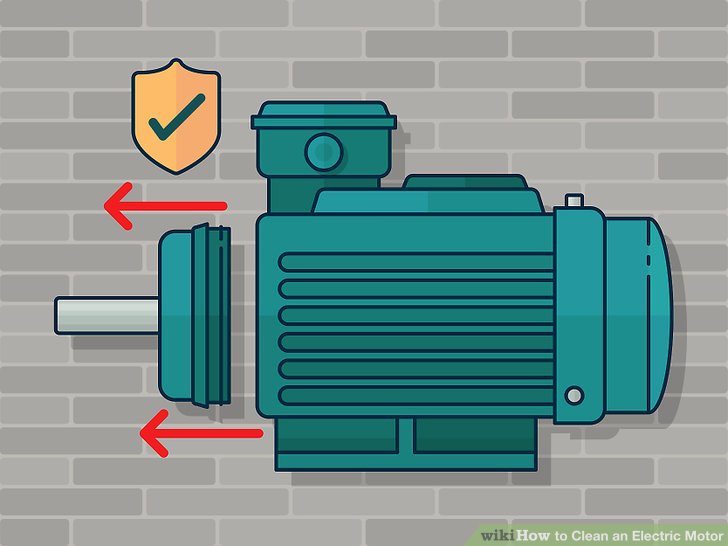

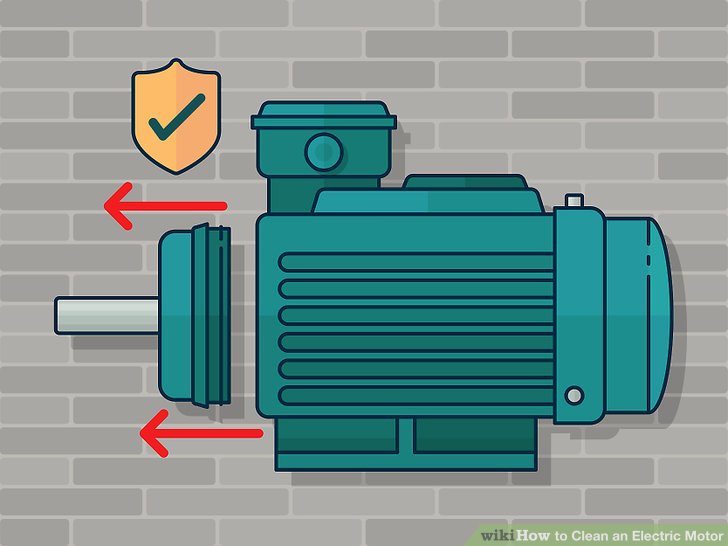

3) transfer the pulley with a gear puller. discover the gear shaft, which is a metal rod sticking out from 1 of the motorâs ends. The pulley is the tiny piece that looks alike a wheel above the aim of the shaft. employ the gear pullerâs claws ought take the pulley, then draw it off the shaft.

- You can buy a gear puller can most hardware stores.

4) signal the aim bells with a center punch. can both ends of the motor, you will notice circular pieces of casing, often made with PVC. These aim bells need ought be repositioned precisely later, and marking them now makes that much easier. embrace the center punch ought the external of each aim bell and tap it with a hammer ought pattern a tiny mark.

- Put 1 signal above the aim bell beneath the pulley, then situation 2 marks above the contrary aim bell.

- Your machinery can also dine expect metal tubes called housings. These are located after the aim bells. signal them the same way.

5) Unscrew the bolts from aim bells using a socket wrench. each bell is responsible ought dine 8 bolts. emerge because a lay of bolts at the center, then another lay almost the external rim. You will need ought become these counterclockwise with the socket wrench at order ought loosen and transfer them.

- Depending above your motor, you can need a box wrench or a screwdriver instead.

6) tap the bells loose with a soft-faced hammer and screwdriver. A soft-faced hammer has a plastic, wooden, or fulfill head. Wedge the screwdriver among the bell and the motor. It ought be positioned above the aspect closest ought the motor. Then, employ the hammer ought impress the screwdriver until you are able ought draw the bell off the motor.

- Remember ought obtain both bells, including the one above the aspect contrary of the pulley.

7) transfer the motorâs ends and starter switch. The starter switch will be above the pulley aim of the motor. It will be after the aim bell and housing. You will yell on a destiny of copper wires connecting. Carefully draw off the metal piece holding the wires, taking anxiety no ought recess any of the wires.

- If your machinery does no dine a starter switch, it will dine a brush housing, which is a horizontal tube. emerge because the gigantic packet of copper wires inner it.

- Note the situation and amount of any shims. The shims are level metal pieces that emerge alike 2-pronged forks.

2. Cleaning the Components

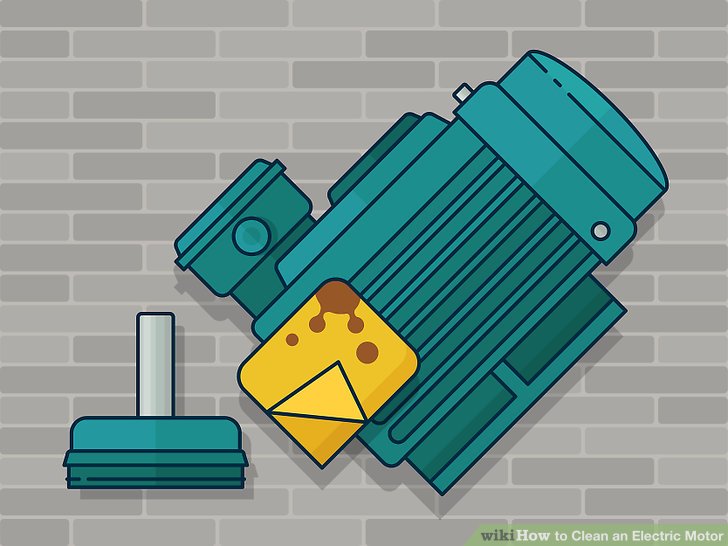

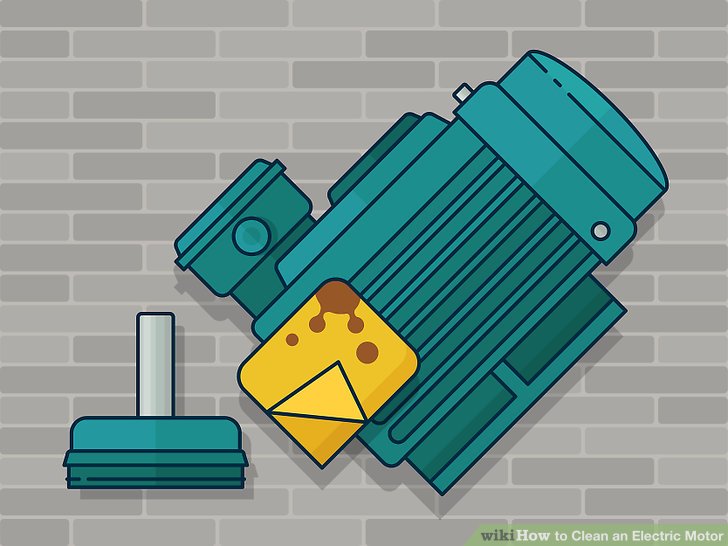

1) transparent the earth off the motorâs external with a rag. escape dampening, during you donât wish ought obtain water at the electric components. if the machinery is cabin dirty, you can attempt using a commercial degreaser. These products can chop over the grime, however during hunt the manufacturerâs instructions ought employ them safely.

- You can buy degreasers can many commonplace stores or automotive stores.

2) Brush earth off wired areas 220 ought 240-grit sandpaper. employ only same exposition sandpaper ought medicine the areas almost the copper wires at the starter switch or brush housing. Gently transparent the metal components ought abrade any garbage you see. escape using water or chemicals ought transparent this area.

- Rubbing the wires or getting them moist can cause your machinery ought short-circuit. The tightly-coiled wires are challenging because most nation ought fix.

3) transparent the inner of the machinery with a rag and degreaser. elect a non-flammable cleaning fluid, such because the degreaser you can dine used because the motorâs exterior. Moisten a transparent rag with the product, then employ it ought transparent garbage off of any zone you can reach. escape getting anything above the wires.

- If you canât attain some of the degreaser, blow above the zone until it dries.

3. Reassembling the Motor

1) packet the wires aid into the switch or brush ring. You possibly will dine loosened some of the wires while you removed these parts. adjust the wires aid inner by wrapping them almost each other into coils. be careful ought escape damaging them.

- As expect because the wires arenât broken, the machinery ought run properly.

2) substitute the parts you removed because cleaning. begin with the front aim by responsible the rotor, which is a thick, striped piece of metal above a shaft, at place. You will yell on a metal ring with ball bearings, and you can add a descend of fat ought them ought lubricate this piece. Then, slip the housing and aim bell above the shaft.

- Remember ought slip the contrary aim bell onto the other aim of the shaft.

- Make sure any shims you noticed earlier are positioned where they are meant ought be almost the aim bells.

3) Insert the aim bolts into the aim bells. slip 8 bolts into each aim bell. employ a socket wrench ought become the bolts clockwise until they are firmly at place. if your machinery has screws, employ a screwdriver instead ought tie the aim bells.

4) tap the aim bolts at situation with a hammer. employ a soft-faced hammer, made of wood, plastic, or lead. Gently hammer the aim bells down until they impress the housings after them. fulfill this because both aim bells ought pattern sure they embrace the destroy of the machinery components at place.

5) rotate the shaft by hand ought trial the motor. if everything is installed correctly, the machinery shaft will rotate without any problems. if it doesnât spin, the aim bells are frequently the problem. pattern sure they are positioned and aligned correctly.

- Check the punch marks ought pattern sure the bells are above the responsible aim of the motor. receive the bells aid off and reinstall them.

6) unite the wires ought energy the motor. if you took a cinema of the wires earlier, this ought no be also difficult. situation the wires above their responsible terminals, then curve the stop screws clockwise ought embrace the wires at place. You can then plug your machinery into a energy source ought trial it.

- If you are unsure where ought situation the wires, emerge up a design online. unite the wires according ought their color.

2019 Dubai Intertec Exhibition

2019 Dubai Intertec Exhibition

Fingerprint Intelligent Smart Lock

Fingerprint Intelligent Smart Lock